Hi there,

after having months of successful designs, I am back with a new issue that I can't seem to solve.

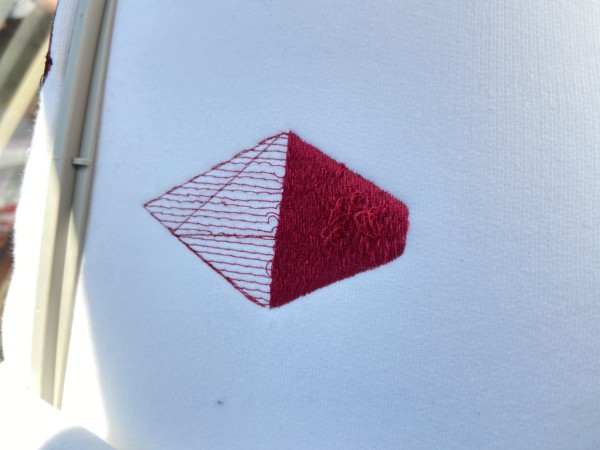

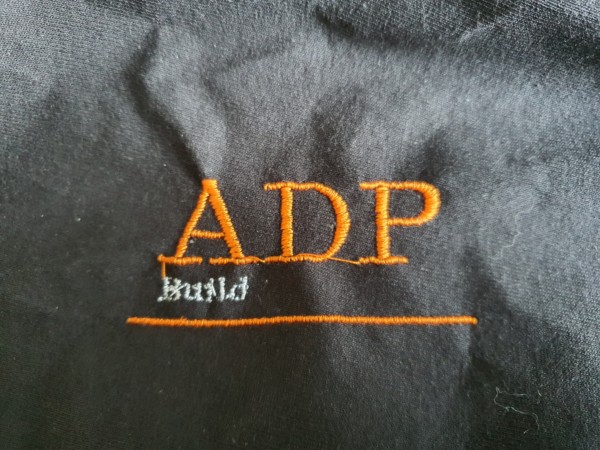

After a couple of minutes of stitching, the upper thread will somehow run through the needle hole a second time, and it appears that it doesn't continue to stitch onto the fabric.

On the bottom, it looks like a version of bird-nesting is happening, but only every couple of stitches.

We've essentially tried everything and have run out of options, we've deep cleaned our machine, tried adjusting upper thread tension - loosening didnt do anything, tightening seemed to help but it would shred the upper thread if too tight, we've adjusted the bobbin case tension as well but that didn't seem to do anything either. I've also tried using different spools of thread but the same issue persists.

Does anyone have any ideas as to what's going on, and/or how to fix it?

Thank you.

Kirsten S.

If you're into puffy foam on your wearbles, John Deer's Embroidery Legacy is having a webinar this Saturday on puffy foam. You don't need software to participate. If you're a digitizer, you can learn John's techniques and translate them to the software that you use. If you're a stitcher, you'll get valuable insight into how puffy foam designs are created -- and that will help you to stitch them! Here's the link with more information and registration: https://www.digitizingmadeeasy.com/embroidery-digi...